Services Provided

- Design and R&D Capabilities1. Can provide services for free2. Team of 115+ professionals3. Single highest experience 43 years4. More than 465 patents5. Custom solutions & collaborative

- Production and Manufacturing1. The Group has five business areas2. Confidential automatic production line 53. Open automatic production line 214. More than 13 years experience per capita5. Support OEM/ODM

- Sales and Partnership1. End-to-end product supply chain solutions2. Bulk order fulfillment (including government contracts)3. Flexible partnership models (e.g. agency/distributor)4. Secure international trade channels5. Provide procurement, logistics and other services

- Service Management1. Provide technical support2. Handling complaints, return, maintenance, etc3. Docking feedback suggestions, etc4. Regular maintenance and upgrades5. The fastest 2 hours to deal with the problem

- Quality Management1. Establish a sound quality management system2. Certifications: CE, RoHS, UL, ISO9001, etc3. Prevention: standard production, FMEA, etc4. Control: SPC, layered inspection, etc5. Continuous optimization through PDCA cycle

Company Introduction

Fuyaoheshan Science and Technology Group, business covers: aerospace, new energy, military equipment, biomedicine, information technology, etc.; it has a full industry process of "design, research and development, manufacturing, warehousing, transportation, orders, and after-sales" to ensure quality And service; representative products: energy storage equipment, solar equipment, aircraft, drone counter-control equipment, medical equipment, etc.

After 20 years of deep cultivation in the industry, there are 5 confidential production lines, 6 fully automatic production lines and 15 semi-automatic production lines, with more than 500 employees and more than 115 core R & D teams. The products cover 80 countries, obtain more than 465 patents and sell more than 1 million products in total.

We can not only provide products and solutions, but also accept your invitation, provide funds, equipment and technology to cooperate with you, build factories and projects with you in your country, and bring you rich benefits and services. We hope to be your partner with sincerity, quality and reliability.

Design and R&D Department

If your company's business needs, we can provide you with free design and R & D services, and we also hope to help partners; we have more than 115 important design and R & D personnel, who have an average of more than 18 years of industry experience, up to 43 years of professional experience; we have obtained 465 kinds of patents, and continue to increase; we look forward to working with you.

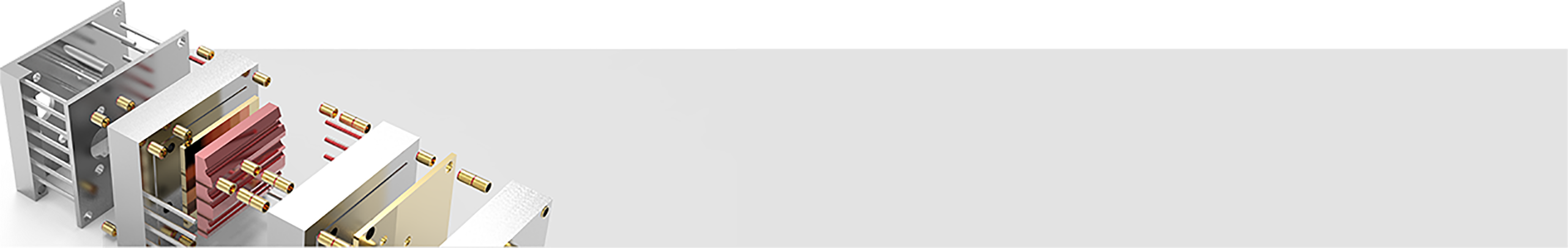

Manufacturing

The group has five major business sectors, including 5 confidential production lines, 6 fully automatic production lines, 15 semi-automatic production lines, as well as various production and manufacturing equipment, inspection equipment, etc., with per capita manufacturing experience of more than 13 years and personal maximum experience of 46 years. Each business line is independent of each other and has a good operation mode. Sufficient capacity supply has enabled many foreign trade companies to purchase products from our group, at the same time, we also supply domestic product demand; we support OEM/ODM.

Global Sales Network

After 20 years of deep cultivation in the industry, the products have covered more than 80 countries and regions, and the cumulative sales of more than 1 million products; we provide product supply chain and safe and reliable transportation channels; we can also complete large-scale order requirements, such as government, chambers of commerce, organizations, Institutional orders; we provide flexible cooperation models, such as agents, distributors, etc., which can be communicated; our company can accept your invitation, cooperate with you in your country, invest money, equipment, technology, etc., build factories, project engineering, etc., to bring you rich benefits and services.

Service Management

The service management department has two teams of technical answering and customer service; the job responsibilities are: ① to provide technical support, ② to deal with complaints, return, exchange, maintenance, etc., ③ to meet customer feedback, suggestions, demand customization, ④ to guide the regular maintenance and upgrading of products, etc;

We can get in touch with you within 2 hours at the earliest and deal with the problem. The time is no more than 12 hours at the latest. We are very willing to communicate with you effectively. If you have good business opportunities, contact us and believe that there will be a pleasant and win-win long-term cooperation.

Quality Management

Our factory has established a complete quality management system (QMS): quality policy and objectives, process and standardization, resource management, supply chain quality control, process control and inspection, data analysis and improvement, document and record management, customer feedback and after-sales service; We strictly implement relevant process standards, formulate quality manuals, procedure documents, operation instructions, and clarify the responsibilities of each department, and through the PDCA cycle (plan-execute-check-improve) continuous optimization process.

In the production process, we implement key control methods, such as: ① standardized operation (SOP), formulate detailed operation standards, ensure the consistency and traceability of the process, and regular training; ② statistical process control (SPC), use control charts (such as X-R chart, P chart, etc.) to monitor the stability of the production process, find abnormalities in time, set upper and lower limits in key parameters, and ensure that they are within the error range; ③ First article inspection and patrol inspection system, full inspection of the first article before each batch of production to ensure that it meets the standards before mass production, and random inspection (such as hours/shift/data volume, etc.) in the production process; ④ Error-proofing design (Poka-Yoke), through physical means such as tooling, sensors, etc. to prevent operation errors.

We have completed ISO 9001, CCC, UL, CE, RoHS and other certification, more quality management methods and strategies, welcome to exchange.